Many domestic liquefied natural gas LNG facilities were initially constructed in the late 1960’s and early 1970’s. As a result, a number of our utility clients are faced with the decision to upgrade, replace, or remove from service their existing storage, liquefaction, and vaporization equipment and systems. Sanborn Head can assist utility operators with assessing existing equipment, evaluating options for future operation, and assisting with capital planning for potential facility upgrade projects.

Key Components:

- Facility Assessment

- Front-end Engineering Design (FEED)

- Alternatives Analysis

- Owner's Engineering

NW Natural owns and operates an LNG liquefaction, storage, and vaporization facility to support its natural gas distribution system during peak demand. The facility’s existing open-loop natural gas expander liquefaction system was installed in the early 1970’s and is approaching its end-of-life. NW Natural engaged Sanborn Head to assist them with developing a strategy for upgrade of its existing system.

Sanborn Head initially worked with our client to identify the existing design basis for the liquefier, with consideration of current feed gas constituents as well as existing tail-gas constraints. We evaluated alternatives for partial or wholesale replacement of the liquefaction equipment, including consideration of alternate technologies such as closed-loop nitrogen liquefaction. Sanborn Head estimated both capital and operating expenses for each option and presented to NW Natural for use in their decision-making process.

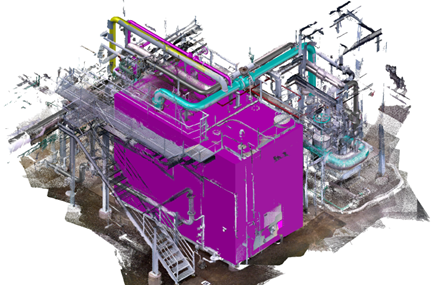

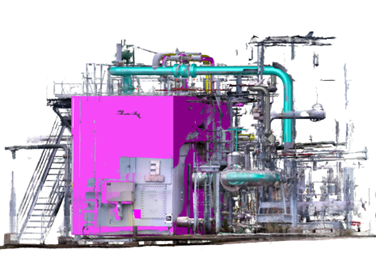

Subsequently, Sanborn Head developed a Front-End Engineering Design to replace the facility’s existing cold box heat exchanger. Our project scope included development of a project design basis, preliminary process, mechanical, electrical, and site designs, and equipment specifications to support procurement of long lead equipment for the project. We utilized our in-house process modelling software and 3D scanning tools to evaluate options for efficient integration of the project with existing process/mechanical piping and systems. Sanborn Head additionally facilitated both a geotechnical evaluation to support preliminary foundation designs, and a wind study in accordance with DOT 49 CFR 193.2067, to define structural design requirements. We conducted a Process Hazards Analysis (PHA) with facility personnel to identify process safety considerations to be incorporated into the project scope.