Data management has become integral to every aspect of business. From day-to-day management of finite resources to having an up-to-date understanding of your asset utilization, it all comes down to maintaining the correct metrics. To complicate things even further, Covid-19 has disrupted many industries with folks retiring earlier than expected, people transitioning to different industries, and people prioritizing work-life balance. With higher turnover and a lot of experience leaving all industries, it has become even more important to have a firm understanding of your business metrics.

In the solid waste industry, aerial and ground survey have been the standard for decades to understand airspace utilization, develop updated fill plans, and plans for the expansion of gas collection and control systems. Some operations have long relied on infrequent ground survey and grade lasers to construct new waste lifts, exterior slopes, etc. Landfill GPS technology has been around since the early 2000s. Since then, geographical-surveying tools have come a long way in ensuring even more optimal compaction rates.

GPS and Drone Tools for Up-To-Date Landfill Metrics

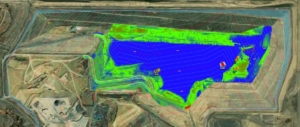

One of the main shortfalls of GPS-enabled tools in the landfill industry is that they are only as accurate as the number of GPS trackers in use. Drone technology offers an affordable option for updating aerial surveys on a more frequent basis than standard flyovers or LIDAR technology. However, the operators in the field still require information to understand where to construct new roads, when they’ve reached base grades for a new cell, or whether they’ve achieved the correct slope on an interim or permanent slope.

The fact is these technologies must be used together along with an updated fill plan to allow for the most up-to-date metrics. Depending on the site’s annual waste volume, updating the topographic surface for use by the GPS system as a base plan can be done on an annual to quarterly basis using drone technology or traditional aerial survey. Using a minimum of one GPS mounted in a dozer or compactor is recommended for each working face of an active landfill. The more terrain a single unit can cover will dictate the accuracy of the data collected using your GPS system. This data, which can be monitored in real time, presents you with an up-to-date understanding of your airspace utilization or compaction, underfilled/overfilled areas, etc.

The Benefits of GPS Technology in Landfill Operations

GPS technology allows its users to construct to the design every time, limiting the need to rework areas. Teams can discuss strategies to improve operations or simply have reassurance that compaction and fill rates are on target for the long-term life of a cell. Other benefits of GPS technology include daily, weekly, and/or monthly compaction reports, accurate remaining fill volume estimates, overfill control, and the ability to track individual pieces of equipment and even individual operators so that you can provide coaching to maximize compaction efficiencies. In addition, your designer can upload the latest design and landfill topography remotely to each piece of equipment. As with anything, this technology needs to be championed to be successful. A discipline needs to be maintained to calibrate or update the equipment periodically.

With an ever-changing workforce situation, site knowledge and general operational experience may disappear. As more and more people decide to work from the comforts of home, there will likely be a shift to more automation and remote-control opportunities in the world of waste management. Having real time GPS data from the field will become a critical component to any landfill management operation with significant tonnages and efficiencies to manage.

Realtime GPS data showing fill operations, and the construction of landfill roads and slopes.

Posted In: Articles

Tagged In: Data, Solid Waste